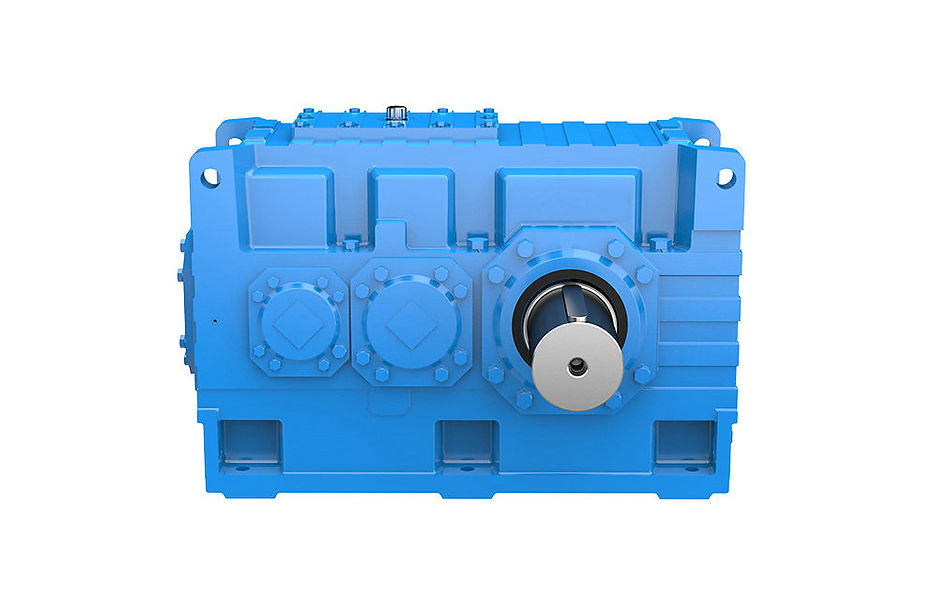

Winch Gearbox

Description:

A gearbox is an important mechanical device used to transmit power and adjust torque and speed in a winch system, which is commonly used for lifting or pulling heavy loads. We provide 2 kinds gearbox for customers: ZFB Series Bevel-Helical Gearboxes and ZFH Series Helical Gearboxes. It can be used for the following fields:

-

Bulk material conveyors for continuous, high-load transport

-

Industrial mixing equipment requiring consistent, high-torque performance

-

Crane and hoist mechanisms demanding precise and reliable lifting power

-

Rotary drying systems operating under sustained thermal and mechanical stress

-

Heavy process machinery used in rigorous, around-the-clock industrial environments

ZFB Series Bevel-Helical Gearbox:

Engineered for industrial strength, the ZFB Series integrates bevel and helical gearing to ensure dependable torque transmission under the toughest conditions. Designed to withstand heavy radial loads, these durable units deliver smooth, consistent performance across a wide range of applications.

These gear units embody our commitment to delivering durable, high-performance power transmission solutions. Engineered with robust construction and precision components, they ensure long service life even in the most demanding environments. The bevel-helical design maximizes torque transfer efficiency while offering flexibility in mounting configurations.

Advantages:

-

Modular design streamlines maintenance and allows for easy customization.

-

Precision-engineered tooth profiles improve load capacity and reduce noise for quieter operation.

-

Reinforced input shafts are built to endure extreme bending moments.

-

Advanced cooling system ensures optimal temperature control during continuous duty cycles.

-

Versatile mounting options support seamless integration into diverse system configurations.

Specifications:

-

Maximum Torque: 900 kNm

-

Power Handling: Up to 400 kW

-

Speed Ratios: 1.25-450:1

Installation Options:

-

Foundation mounting for stable, fixed installations

-

Flange connection for compact and secure assembly

-

Axle-mounted with torsion arm for flexible, vibration-resistant setups

-

Custom configurations available to meet unique application requirements

Highlights:

-

Optimized gear tooth geometry minimizes operational noise for quieter performance

-

Heavy-duty bearings accommodate high radial loads with enhanced durability

-

Efficient thermal management system ensures reliable performance under continuous use

-

Rugged housing construction provides long-lasting protection in harsh environments

-

Precision-machined gear sets deliver accurate, reliable torque transmission

ZFH Series Helical Gearbox:

The ZFH Series Helical Gearboxes deliver dependable power transmission across a wide range of sectors. Offered in both parallel shaft (DLH) and bevel-helical (DLB) designs, they support versatile mounting configurations—horizontal, vertical, or customized to fit specific installation needs. These gearboxes can be used for the fields as blow:

-

Conveyors for bulk material handling

-

Industrial mixers and agitators

-

Cranes and hoisting systems

-

Rotary dryers, kilns, and similar thermal processing equipment

-

A wide range of heavy-duty industrial drive applications

Key Features:

-

Modular design allows for standardized manufacturing while supporting tailored configurations

-

Optimized gear tooth profiles improve load handling and reduce noise levels

-

Robust input shaft design resists heavy radial forces and bending stresses

-

Versatile sealing options provide reliable oil leak prevention, even in challenging environments

-

High-precision helical gears deliver smooth, low-vibration power transmission

-

Durable housing made from robust cast iron or welded steel

-

Helical gears are hardened and precision-ground for enhanced performance

-

Stepped torque transmission ensures efficient power flow and load distribution

-

Gears manufactured from high-strength 20CrMnTi alloy steel

-

Supplied in standard wooden case packaging for secure transport and storage

Parameters:

-

Power Range: 1.7 to 10,000 kW

-

Torque Capacity: Up to 900 kNm

-

Input Speeds: 750 / 1000 / 1500 rpm

-

Gear Material: Case-hardened 20CrMnTi alloy steel

-

Housing Types: Cast iron or welded steel plate construction

-

Speed Ratios: 1.25:1 to 450:1

-

Output Speed Range: 1.7 to 1200 rpm

-

Mounting Options: Horizontal or vertical configurations

-

Manufacturing Process: Precision forging followed by high-accuracy grinding

-

Protection Features: Multiple advanced sealing systems for leak prevention

CONTACT

Contact Us

Address

No. 158, East Section of Wei 11th Road, Crane Industrial Park, Weizhuang Town, Changyuan City, Henan Province

Email: david@zfcrane.com

WhatsApp: +86-1750-3832-559

WhatsApp WeChat